Well I am now officially blogging from KL, after finishing my role with GHD in Manila.

My new role sees me working as the Company BIM Manager for YTL Corporation with our internal, Owners, Designers, Construction and Operations team to help leverage new technologies like BIM to centralise and streamline information for our stakeholders.

My family is settled and I am working on some exciting stuff, templates, API and already helping co-ordinate some very projects which I hope to show case at some point.

Anyway as always sitting down and start from scratch brings new perspectives with experience and here is a trick that has been around for a few releases but I have never thought of using till this morning.

So a big issue with Architects and Engineers with Revit, is that whilst you can get FFL and SSL it's hard to have step downs as they are relative to the floors they are stepping down from only.

So after planning to create the new step down symbol I thought how to make it intelligent and a thought came to me, Adaptive families.

Since all adaptive components can have multiple points and be faced based on selection I thought why not create a simple 2 point adaptive component, a shared reporting parameter and a tag.

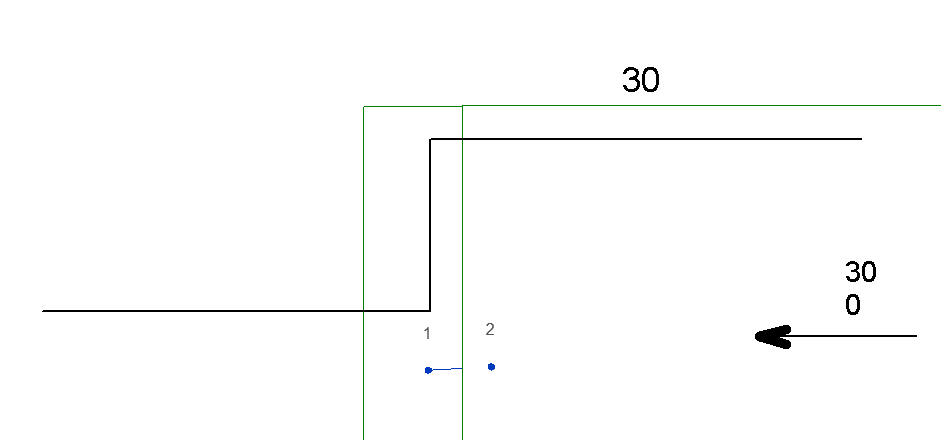

Here is my mockup.

First create a generic adaptive component, create an additional level by coping the level up, then place a point of each level. I then created a shared parameter that is connected in the Z axis only to the elements like so.

I drew an invisible line that is 3D point based to make selection and manipulating easier in my project.

From there is was a matter of creating a tag and referencing the shared parameter as a label.

After this it is connecting the step down adaptive component to the two faces of the floors and tag the element from which you will get the reporting step down's and it will update automatically when the slabs/finishes/step downs change.

Also if the floors or finishes are removed it will automatically delete the element and tag so be sure to rehost if you need to host to a different element.

I will be at RTC in a few weeks and I hope to see many of you there.

A blog on various musings, issues and technical solutions for Autodesk, Bentley, Cloud, Civil, Coding, Rendering & anything else that I run into during my working day!

Tuesday, May 6, 2014

Wednesday, March 26, 2014

Point Cloud beginer tips

A project I am working on at the moment is a complex Hotel that is requiring a complete refurb on an extremely tight deadline.

This project is located overseas from my office here and I have been collating and managing the team to capture the existing conditions, we are modeling the entire structure in Revit.

To speed the process we have been getting the whole building point cloud scanned, and so whilst I have dabbled in LiDAR and point clouds on a few projects this is my first project in which we are dealing with them on a day to day basis, and a large volume of data aswell.

So to begin with I have been using ReCAP, which is pretty simple to use view, cut/crop and then export the clouds for various uses.

However before that I needed the data in a usable format, due to the surveyor initially providing us raw data which was useless, I managed to find a text file that told me the make of scanner Leica and used that to determine what data the default technology can export, and asked for that from our surveyor.

To date we have been asking and dealing with pts files, however I have since been told (Thanks Brett from Autodesk) that ptg is a better format as it's ascii readable and therefore there are less translations woe's so in future this is the format we will be requesting.

Our second issue has been converting the exported files to the Autodesk recap/scan files, as these files can be anywhere from a couple of gig to 150gb this can take a long time, the first couple of scans were being copied across to our server and then converted with the copy/conversion process taking up to a day for the larger scans.

We have since setup a computer in the project office and I remote in to that, as the conversion from the point file to Autodesk scan file can drop the size of a file by as much as 70%. We then copy the converted file across enabling our team instant access to the new data once it has been copied. We did have an issue with the graphics card not being able to run the right version of OpenGL in a remote desktop session, so in this case we needed another computer in order to get access to ReCAP.

The first thing I recommend when using recap is to set your temporary folder to somewhere where you have ALOT of hdd space. Our conversions of large scans say for instance a 45gb required an additional 65gb of conversion space to convert the file to the Autodesk format.

Our office standard is small SSD C drives and with all the other software I only have about 40gb spare at the moment so change this in your settings.

I will post some more key things in the future, but the major ones I have learned are;

Change your temporary folder locations for conversion

If you need to move cloud file between offices, convert them first to lower transfer times.

Ask for ptg files for readability

Using Remote Desktop services may be an issue if your card doesn't support at least OpenGL 3.1 for remote services.

Otherwise I have had no issues with locations or grid co-ordinates when loading files into Revit, I will provide additional updates on tips & tricks.

This project is located overseas from my office here and I have been collating and managing the team to capture the existing conditions, we are modeling the entire structure in Revit.

To speed the process we have been getting the whole building point cloud scanned, and so whilst I have dabbled in LiDAR and point clouds on a few projects this is my first project in which we are dealing with them on a day to day basis, and a large volume of data aswell.

So to begin with I have been using ReCAP, which is pretty simple to use view, cut/crop and then export the clouds for various uses.

However before that I needed the data in a usable format, due to the surveyor initially providing us raw data which was useless, I managed to find a text file that told me the make of scanner Leica and used that to determine what data the default technology can export, and asked for that from our surveyor.

To date we have been asking and dealing with pts files, however I have since been told (Thanks Brett from Autodesk) that ptg is a better format as it's ascii readable and therefore there are less translations woe's so in future this is the format we will be requesting.

Our second issue has been converting the exported files to the Autodesk recap/scan files, as these files can be anywhere from a couple of gig to 150gb this can take a long time, the first couple of scans were being copied across to our server and then converted with the copy/conversion process taking up to a day for the larger scans.

We have since setup a computer in the project office and I remote in to that, as the conversion from the point file to Autodesk scan file can drop the size of a file by as much as 70%. We then copy the converted file across enabling our team instant access to the new data once it has been copied. We did have an issue with the graphics card not being able to run the right version of OpenGL in a remote desktop session, so in this case we needed another computer in order to get access to ReCAP.

The first thing I recommend when using recap is to set your temporary folder to somewhere where you have ALOT of hdd space. Our conversions of large scans say for instance a 45gb required an additional 65gb of conversion space to convert the file to the Autodesk format.

Our office standard is small SSD C drives and with all the other software I only have about 40gb spare at the moment so change this in your settings.

I will post some more key things in the future, but the major ones I have learned are;

Change your temporary folder locations for conversion

If you need to move cloud file between offices, convert them first to lower transfer times.

Ask for ptg files for readability

Using Remote Desktop services may be an issue if your card doesn't support at least OpenGL 3.1 for remote services.

Otherwise I have had no issues with locations or grid co-ordinates when loading files into Revit, I will provide additional updates on tips & tricks.

Monday, February 17, 2014

CAD Links Project File

I have noticed lots of people struggle with Xref CAD Linked files on Revit Servers.

This can be due to a number of things different folder location setups for each office, getting Consultant or Client required drawings, in which you need to link to your Revit model.

The easiest way for me to do this is by creating a new Revit Model called CADLinks or something similar.

Once this project is created Copy/Monitor Levels and Grids from your actual Project.

Then for floor, elevation, section views simply setup multiple views for each level for CAD Link as required then load them in, ensuring that the Links are in the correct positions with the Grids/Levels.

I normally make sure each link is then set to Foreground in the views. This will ensure that the CAD file overlays ontop of the floors or other model elements in the Project.

Once this is setup I activate worksharing and save the file to the Revit Server.

Then in my main Project file I load this file in onto it's own Workset and then for any views that require a Linked view for any reason you can just setup the View Settings with the Linked By View option and the correct CAD Linked view selected.

This way if other offices work on the Work in progress file there is no double of CAD Files, plus in your Master file there are no linked CAD files at all, which means no issues with CAD files being duplicated, or loaded into the distance.

Other issues I've encountered is bad CAD files or Objects in CAD files causing problems in project files, cleaning up the amount of links in your direct Project File.

This also speeds up reference loading since all the data for the linked views is stored in the Revit File Memory so it doesn't need to load 100's of references if your consultants have been using CAD or you are working with large civil datasets and drawings.

This can be due to a number of things different folder location setups for each office, getting Consultant or Client required drawings, in which you need to link to your Revit model.

The easiest way for me to do this is by creating a new Revit Model called CADLinks or something similar.

Once this project is created Copy/Monitor Levels and Grids from your actual Project.

Then for floor, elevation, section views simply setup multiple views for each level for CAD Link as required then load them in, ensuring that the Links are in the correct positions with the Grids/Levels.

I normally make sure each link is then set to Foreground in the views. This will ensure that the CAD file overlays ontop of the floors or other model elements in the Project.

Once this is setup I activate worksharing and save the file to the Revit Server.

Then in my main Project file I load this file in onto it's own Workset and then for any views that require a Linked view for any reason you can just setup the View Settings with the Linked By View option and the correct CAD Linked view selected.

This way if other offices work on the Work in progress file there is no double of CAD Files, plus in your Master file there are no linked CAD files at all, which means no issues with CAD files being duplicated, or loaded into the distance.

Other issues I've encountered is bad CAD files or Objects in CAD files causing problems in project files, cleaning up the amount of links in your direct Project File.

This also speeds up reference loading since all the data for the linked views is stored in the Revit File Memory so it doesn't need to load 100's of references if your consultants have been using CAD or you are working with large civil datasets and drawings.

Tuesday, January 21, 2014

VEO 1.7.0 Update

Latest update of VEO is out, and damn the models are flying, they seem to really focus on making things faster and faster as well as improving on existing features as well as adding new ones.

Some great new features like measure and a status bar type UI element for allowing quick access to items and keeping track of your sync'ing and projects.

An important thing to note, for those outside North America we can access the Track module, this basically allows people out on site to scan barcodes and it will select various models, documents, or go to views based on the requirements back in the office for communication of issues and other problems.

Now this has been disabled by default however if you contact m-six support they will activate your account with this feature, if you are allowed to use it in your region at last check North America was unable to use this function.

Kudos to the Team, and looking forward to seeing more great enhancements to old features, speed and the addition of new features!!!

Some great new features like measure and a status bar type UI element for allowing quick access to items and keeping track of your sync'ing and projects.

An important thing to note, for those outside North America we can access the Track module, this basically allows people out on site to scan barcodes and it will select various models, documents, or go to views based on the requirements back in the office for communication of issues and other problems.

Now this has been disabled by default however if you contact m-six support they will activate your account with this feature, if you are allowed to use it in your region at last check North America was unable to use this function.

Kudos to the Team, and looking forward to seeing more great enhancements to old features, speed and the addition of new features!!!

Tuesday, January 14, 2014

Conversion of Large Site Datasets for Visualisation

As an engineering firm with a very large Civil/Water team we do a lot of work with LiDAR surfaces and the like. These objects tend to be very top heavy although having them in their entirety in our rendering presentations certainly goes a long way to achieving not only a more realistic presentation for our clients, but as a interactive model for our engineers.

We use a number of platforms for our civil works and road designs due to our client requirements and simply some tools are better then others or some users prefer a tool and are good at their jobs, on any typical day in our office we have teams on 12D, Autodesk Civil3D, Bentley MX and/or Geopak.

Fortunately Autodesk acquired a tool a few years ago that imports all these tool sets called Civil View(Used to be Dynamite), built into 3DS Max Design as of 2014. Prior versions it was an addon bundled with the software.

Anyway as string/alignment designs (strings/alignments are a very important tool civil designer use to create roads, kerbs, drainage from a single polyline connected to an assembly, for Revit people think of sweeps that could auto cut/fill topography, as well as create the object) paths and surfaces can be complex sometimes the routines do not always play that nicely with bringing data in, other times it can simply be the size of the datasets. As a importation tool though for us it really does a great job to quickly create very large Civil Visualisations and Conceptual Options for stakeholders who are typically council, government related, and add visual enhancements like vehicles, road signage and that sort of thing.

String/feature lines in 3DS Max are only require if you want a line to layout objects like vehicles, traffic lights, signage etc.... otherwise they are not doing a huge amount for your file.

3ds Max is very stable with very large geometric datasets, and I've yet to create something for visualisation so unwieldy it was unable to handle the data, I should point out we use a GPU rendering tool and Max is our file container and manager of complex and large scene data, we don't use the rendering tools in it, only the animation and scene setups.

An example is the following of which I have been able to get the road designs and PAD's across but the software was unable to convert the main LiDAR surface from Civil3D.

In these case the surface wouldn't come across and the warnings in the export from Civil3D tell me that aswell. If you are guiding a Civil Engineer through this process make sure they tell you if there are any errors in the export to save any hassle with trying to figure out why Max isn't working, when it's not the issue.

As with any failures it's time to drop to the next attempt at importation and that's using landXML. LandXML is a pretty good format for exchanging data, however like IFC or DXF it creates large files that describe geometry and not design intent, most Civil programs work in similar fashion and the conversion is generally pretty good except for things like super elevations, assemblies and the like.

Anyway so I exported the LiDAR surface only, this generated a 1.5gig file. Now bringing this into 3ds Max takes a long time so make sure this is done as an overnight activity to not tie up resources. The final Max file was around 450mg and runs relatively very quick.

In this scenario I used the Export to Civil View for 3ds max tool, the other import tools in Max require the right settings from 12D or MX but there is no need for custom formats or exports like Civil3D. For 12D simply ask your civil designers for the main files they should be saved as ASCII format already, or depending on how they built their models you might want them to combine it all in a single export. 12D files handle large datasets for better then Civil3D without having to split files and create additional CAD management so in many cases our largest projects are done in 12D.

If you need complex scene animations, 4D, Road analysis or phasing your best to discuss with your Civil engineer what you are trying to achieve and if they are agreeable you can get them to quickly build a number of joined and split surfaces both existing and during/post construction to get the surfaces you need.

The end results really make a big difference on large civil projects with little time investment.

We use a number of platforms for our civil works and road designs due to our client requirements and simply some tools are better then others or some users prefer a tool and are good at their jobs, on any typical day in our office we have teams on 12D, Autodesk Civil3D, Bentley MX and/or Geopak.

Fortunately Autodesk acquired a tool a few years ago that imports all these tool sets called Civil View(Used to be Dynamite), built into 3DS Max Design as of 2014. Prior versions it was an addon bundled with the software.

Anyway as string/alignment designs (strings/alignments are a very important tool civil designer use to create roads, kerbs, drainage from a single polyline connected to an assembly, for Revit people think of sweeps that could auto cut/fill topography, as well as create the object) paths and surfaces can be complex sometimes the routines do not always play that nicely with bringing data in, other times it can simply be the size of the datasets. As a importation tool though for us it really does a great job to quickly create very large Civil Visualisations and Conceptual Options for stakeholders who are typically council, government related, and add visual enhancements like vehicles, road signage and that sort of thing.

String/feature lines in 3DS Max are only require if you want a line to layout objects like vehicles, traffic lights, signage etc.... otherwise they are not doing a huge amount for your file.

3ds Max is very stable with very large geometric datasets, and I've yet to create something for visualisation so unwieldy it was unable to handle the data, I should point out we use a GPU rendering tool and Max is our file container and manager of complex and large scene data, we don't use the rendering tools in it, only the animation and scene setups.

An example is the following of which I have been able to get the road designs and PAD's across but the software was unable to convert the main LiDAR surface from Civil3D.

In these case the surface wouldn't come across and the warnings in the export from Civil3D tell me that aswell. If you are guiding a Civil Engineer through this process make sure they tell you if there are any errors in the export to save any hassle with trying to figure out why Max isn't working, when it's not the issue.

As with any failures it's time to drop to the next attempt at importation and that's using landXML. LandXML is a pretty good format for exchanging data, however like IFC or DXF it creates large files that describe geometry and not design intent, most Civil programs work in similar fashion and the conversion is generally pretty good except for things like super elevations, assemblies and the like.

Anyway so I exported the LiDAR surface only, this generated a 1.5gig file. Now bringing this into 3ds Max takes a long time so make sure this is done as an overnight activity to not tie up resources. The final Max file was around 450mg and runs relatively very quick.

In this scenario I used the Export to Civil View for 3ds max tool, the other import tools in Max require the right settings from 12D or MX but there is no need for custom formats or exports like Civil3D. For 12D simply ask your civil designers for the main files they should be saved as ASCII format already, or depending on how they built their models you might want them to combine it all in a single export. 12D files handle large datasets for better then Civil3D without having to split files and create additional CAD management so in many cases our largest projects are done in 12D.

If you need complex scene animations, 4D, Road analysis or phasing your best to discuss with your Civil engineer what you are trying to achieve and if they are agreeable you can get them to quickly build a number of joined and split surfaces both existing and during/post construction to get the surfaces you need.

The end results really make a big difference on large civil projects with little time investment.

Sunday, January 5, 2014

Revit Server 2013 Model Corruption!!

Hey Guys

Happy New Year and I hope all enjoyed their holidays.

Here is a quick issue we have encountered and never knew about, if anyone is deleting models from Revit Server 2013 whilst any other users on ANY OTHER project on the server are synchronising within a couple of minutes of the Host server replicating the deletion changes with the Accelerators then the model they are working on will become corrupt.

So make sure any cleanup of the Revit Server 2013 is done outside of hours when people aren't working.

PS Revit Server 2014 does not seem to have this issue.

Happy New Year and I hope all enjoyed their holidays.

Here is a quick issue we have encountered and never knew about, if anyone is deleting models from Revit Server 2013 whilst any other users on ANY OTHER project on the server are synchronising within a couple of minutes of the Host server replicating the deletion changes with the Accelerators then the model they are working on will become corrupt.

So make sure any cleanup of the Revit Server 2013 is done outside of hours when people aren't working.

PS Revit Server 2014 does not seem to have this issue.

Monday, December 16, 2013

Correct Annotation Orientation of Sloped Details in Revit.

Ok RTC talks for both AUS and USA are in, for those who don't know if you log in to the RTCAUS submit speaker tool you can actually see if your talk has been accepted or not for RTCAUS only.

However not sure how official this is until the actual emails of confirmation go out, but check anyway!!

A user had an interesting issue the other day, I have replicated a simple version for example.

Basically he wanted an angled detail showing the true length of the member, here is a simple layout below of the project.

Now you can see in the Elevation he has gone ahead and drawn a Detail Section View as you cannot draw sections on angles.

Now when the view generated it did two interesting things, first the changed from Vertical layout to Horizontal, and any attempts to rotate the crop box fail, you can rotate it successfully to any but 90 degrees.

However we were able to place it on a sheet and use the rotate sheet view as seen below.

Once we applied dimensions they weren't correct orientation nor was the detail view title as you can see.

So with this in mind we thought we would try to create an assembly view, one thing not commonly know about assemblies if you can modify the orientation to generate views automatically based on the Origin Point.

So we selected the object and made the frame into an assembly, then we edit the assembly, you can see the dot and we just need to move it to the correct height and then rotate the point to match the angle of the framing you might need to set your workplanes for this.

Your point should reflect something like the following.

Once you have done this you should see the framing plan similar to before only this time you can actually rotate the crop boxt to 90 degrees and then place it on the sheet correctly.

Placing this on a sheet then rotating did not fix the issue, so you must rotate the cropbox.

You will get correct orientation of titles, dimensions and tags.

Obviously a downfall is this only works with items that can work with assemblies.

Alright I'm off on holidays with the family, so safe travels and merry xmas, happy new year and hopefully I will kick off with some of the other things I am doing with Dynamo and the API.

However not sure how official this is until the actual emails of confirmation go out, but check anyway!!

A user had an interesting issue the other day, I have replicated a simple version for example.

Basically he wanted an angled detail showing the true length of the member, here is a simple layout below of the project.

Now you can see in the Elevation he has gone ahead and drawn a Detail Section View as you cannot draw sections on angles.

Now when the view generated it did two interesting things, first the changed from Vertical layout to Horizontal, and any attempts to rotate the crop box fail, you can rotate it successfully to any but 90 degrees.

However we were able to place it on a sheet and use the rotate sheet view as seen below.

Once we applied dimensions they weren't correct orientation nor was the detail view title as you can see.

So with this in mind we thought we would try to create an assembly view, one thing not commonly know about assemblies if you can modify the orientation to generate views automatically based on the Origin Point.

So we selected the object and made the frame into an assembly, then we edit the assembly, you can see the dot and we just need to move it to the correct height and then rotate the point to match the angle of the framing you might need to set your workplanes for this.

Your point should reflect something like the following.

Once the location is set you can then generate your views, anytime you make a plan detail view always make an elevation or section view, this is because by default the plan views ends up cutting the middle of the assembly and you need to move the section marker in the assembly elevation view above all the objects to see all the members.

Placing this on a sheet then rotating did not fix the issue, so you must rotate the cropbox.

You will get correct orientation of titles, dimensions and tags.

Obviously a downfall is this only works with items that can work with assemblies.

Alright I'm off on holidays with the family, so safe travels and merry xmas, happy new year and hopefully I will kick off with some of the other things I am doing with Dynamo and the API.

Subscribe to:

Posts (Atom)